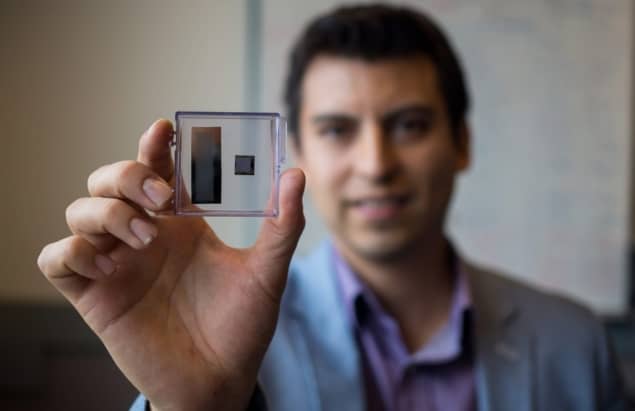

Engineers at the University of British Columbia (UBC) have developed and fabricated a novel ultrasound transducer that could lower the cost of ultrasound scanners to as little as $100. Their patent-pending device is portable, can be powered by a smartphone and could pave the way for creating wearable ultrasound devices (Microsystems & Nanoengineering 10.1038/s41378-018-0022-5).

Conventional ultrasound scanners use piezoelectric crystals to create images. The UBC team replaced the piezoelectric crystals with tiny vibrating drums made of polymer resin, called polyCMUTs (polymer capacitive micro-machined ultrasound transducers). CMUTs exhibit certain advantages over their piezoelectric counterparts, such as wider bandwidth, better integration with electronics and ease of fabricating large arrays. The use of inexpensive polymers, meanwhile, lowers the cost of manufacture.

“Transducer drums have typically been made out of rigid silicon materials that require costly, environment-controlled manufacturing processes, and this has hampered their use in ultrasound,” explains lead author Carlos Gerardo, a PhD candidate at UBC. “By using polymer resin, we were able to produce polyCMUTs in fewer fabrication steps, using a minimum amount of equipment, resulting in significant cost savings.”

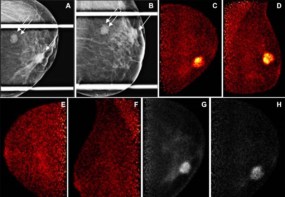

To test their technology, Gerardo and colleagues used a 64-element polyCMUT array to image a phantom made from 12 aluminium wires in a tank of mineral oil. The generated B-mode image showed that all of the wires could be identified, down to a depth of 85 mm. For the first five wires (down to a depth of 50 mm) the full-width at half-maximum revealed a lateral resolution of better than 1.5 mm.

Sonograms produced by the UBC device were as sharp as, or even more detailed than, traditional sonograms produced by piezoelectric transducers, says co-author Edmond Cretu. “Since our transducer needs just 10 volts to operate, it can be powered by a smartphone, making it suitable for use in remote or low-power locations,” he adds. “And unlike rigid ultrasound probes, our transducer has the potential to be built into a flexible material that can be wrapped around the body for easier scanning and more detailed views — without dramatically increasing costs.”

The authors note that the technology has the potential to be extended to flexible substrates to create conformal and wearable health monitoring systems. Another advantage is that the maximum processing temperature is 150 °C, potentially enabling polyCMUTs to be fabricated directly on top of substrates containing pre-existing components.

The next step in the research is to develop a wide range of prototypes and eventually test the device in clinical applications. “You could miniaturize these transducers and use them to look inside your arteries and veins. You could stick them on your chest and do live continuous monitoring of your heart in your daily life. It opens up so many different possibilities,” says co-author Robert Rohling.