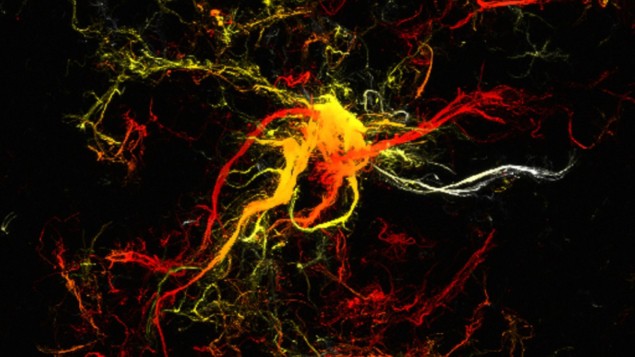

Turbulence – the culprit behind the heart-stopping moments on a bumpy aeroplane ride – is unpredictable and difficult to control, but it can come in handy sometimes. Now, Orlin Velev and colleagues at North Carolina State University have harnessed the power of turbulence to develop a versatile method for synthesizing dendritic polymer particles. These dendritic polymers have nanoscale wispy tendrils bearing striking structural similarities to the soles of gecko feet. They show promise for a wide range of applications from adhesives to gelation agents for cosmetics and foods.

A dissolved polymer that is exposed to a “bad” solvent in which the polymer is not soluble will precipitate. The shape of the polymer precipitate can be tuned by how rapidly the bad solvent is flowing around the polymer solution droplet.

Turbulence is associated with fast, chaotic flow. When the researchers injected a dissolved polymer into a bad solvent that was flowing at extremely high shear rates, the polymer was dispersed by the new solvent medium in all directions as it precipitated. This gave rise to dendrites that resemble split ends upon split ends that you might experience on an extremely bad hair day.

Surprisingly organized

“Turbulent flow is highly disorganized; nevertheless, when we precipitate polymers under these conditions, the resulting polymer structures exhibit multiscale branching,” said Velev. “This is surprising because turbulent flow is not expected to organize materials, but that is what we see in our structures.”

Velev calls the materials organized because the polymer dendrites are hierarchically structured like Russian dolls. The micron-thick cores of the polymers branch repeatedly, until the very tips of the strands are thousands of times finer.

As a result, the polymers have a huge surface area. This allows the omnipresent attractive van der Waals forces to act between the polymer and any surface it comes into contact with. Such a structure makes the polymer sticky – indeed, it resembles the bottom of gecko feet at the nanoscale.

Sticky situation

Almost any polymer can be processed into sticky dendrites via turbulent shearing regardless of its original structure or chemical makeup, as long as it can be dissolved.

When the researchers dried dendritic cellulose acetate between two glass slides, the lap shear force required to pull the slides apart was larger than that for double-sided adhesive tape. Cellulose acetate is typically not a sticky polymer, but the researchers had transformed it into a glue that outperforms common household adhesives.

Static electricity helps geckos get a grip

The study shows that dendritic polymers have potential for other applications, such as mechanically resilient porous sheets or gelation agents. Velev also wants to untangle the mathematically inaccessible principles of turbulent flow, at least in the context of polymer precipitation.

“Turbulent flow is intriguing, but it is complex,” says Velev. “Copious fundamental work needs to be done to understand the correlation between the flow parameters, the size of the fluid eddies, and the nanofibres in the dendritic colloids. We hypothesize that they are all correlated and aim to develop a model for the correlations.”

The research is described in Nature Materials.