A new way of creating specially shaped pulses of ultrasound using light and a 3D printer has been unveiled by Michael Brown and colleagues at University College London. The pulses, which are creating using the photoacoustic effect in a 3D-printed material, could be tailored to perform a range of tasks including manipulating biological cells and delivering drugs to specific parts of the body.

Renowned for its ability to let us see inside the body, ultrasound refers to acoustic waves at frequencies above about 20 kHz. Such waves can also be used for medical treatment, industrial product imaging and chemistry. Researchers have also recently developed acoustic tractor beams and tweezers for the non-contact manipulation of small objects.

Ultrasound is usually generated by applying an electrical signal to a piezoelectric transducer. Complicated ultrasound signals can be created using arrays of transducers, but the ability to create certain very precise waveforms would require many tiny components – making such ultrasound generators expensive.

Heating up

Brown and colleagues’ technique to create specific ultrasound waveforms involves using a light signal, such as a laser pulse, to heat part of an object so it locally expands. This triggers vibrations that travel out from the surface of the material as sound waves. The precise nature of the ultrasound wave is defined by the 3D shape of the surface of the photoacoustic material.

To create surfaces that output specific ultrasound signals, the team developed an algorithm that calculates the 3D surface profile required to create a desired ultrasound signal. “Our algorithm allows for precise control of the intensity of sound at different locations and the time at which the sound arrives, making it quick and easy to design surfaces or ‘lenses’ for a desired application,” says Brown.

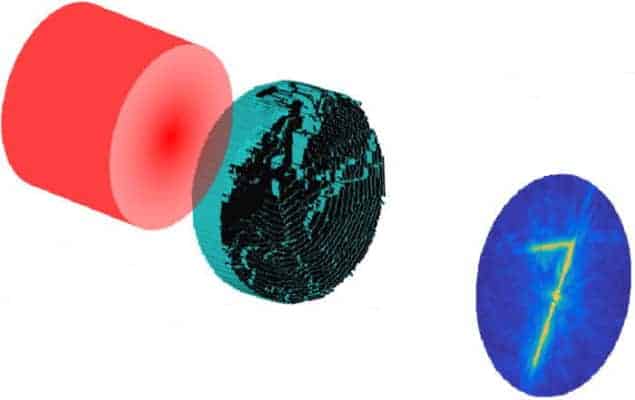

At the heart of their ultrasound generator is a 3D-printed cylinder of transparent material. One end of the cylinder is flat, while the other has a 3D pattern picked specifically to create an ultrasound wave in the shape of the numeral “7” (see figure). The patterned surface is then coated with black plaint, which makes it a good absorber of light.

To create an ultrasound pulse, a laser pulse is fired at the flat end of the cylinder. The light travels through the cylinder and strikes the paint at the opposite end, where ultrasound waves are emitted from the surface of the cylinder into a tank of water containing an ultrasound detector.

Using this set-up, Brown and colleagues were able to create and detect ultrasound waves shaped like a “7”. But as well as creating pulses with complicated shapes, the technique could also be used to create intense ultrasound pulses. “One useful feature of the photoacoustic effect is that the initial shape of the sound that’s generated is determined by where the light is absorbed,” explains Brown. “This can be used to create tightly focused intense points of sound just by depositing an optical absorber on a concave surface, which acts like a lens.”

Tiny bubbles

One possible application of the ultrasound generator is to create acoustic tweezers that can manipulate living cells and other delicate objects without any physical contact. Another possible use, according to Brown, is the targeted delivery of drugs. This would involve encapsulating the drugs in tiny bubbles that burst only when exposed to an ultrasound signal at, say, the site of a tumour.

The technique could also be used to correct for distortions to ultrasound signals as they travel through tissue or other materials. If the structure of the material is known beforehand, an ultrasound generator that compensates for the distortions can be made. So far, limitations in laser power have restricted the team to using pulsed lasers, but Brown says that the team is also interested in generating ultrasound using continuous-wave optical signals.

The new technique is described in Applied Physics Letters.