This year marks the 20th anniversary of the first time an optical-frequency comb was used to measure the atomic hydrogen 1S-2S optical transition frequency, which was achieved at the Max-Planck-Institut für Quantenoptik (MPQ) in Garching, Germany. Menlo Systems, which was founded soon afterwards as a spin-off from MPQ, has been commercializing and pioneering the technology ever since.

Today, optical frequency combs (OFCs) are routinely employed in applications as diverse as time and frequency metrology, spectroscopy, telecommunications, and fundamental physics. The German company’s fibre-based systems, and its proprietary “figure 9” laser mode-locking technology, have set the precedent for the most stable, reliable, robust, and compact optical frequency combs available on the market today.

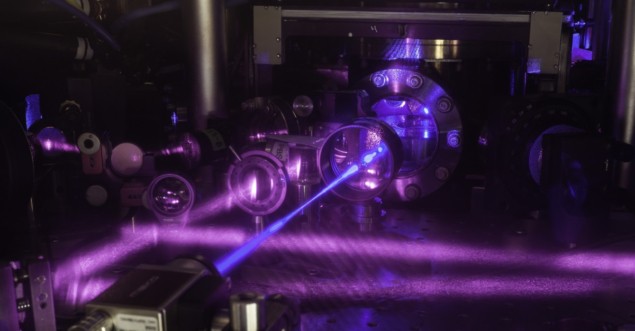

An optical frequency comb exploits laser light that comprises up to 106 equidistant, phase-stable frequencies to measure other unknown frequencies with exquisite precision, and with absolute traceability when compared against a radiofrequency standard. The most common and versatile approach to create an OFC is to stabilize an ultrafast mode-locked laser, in which pulses of light bounce back and forth in an optical cavity. The frequency spectrum of the resulting pulse train is a series of very sharp peaks that are evenly spaced in frequency, like the teeth of a comb.

Through the so-called self-referencing technique, the first tooth of the comb – called the carrier-to-envelope offset frequency – is well fixed to a certain position. When the spacing of the comb teeth is referenced to a known frequency, such as the radiofrequency generated by a caesium atomic clock or a hydrogen maser, the absolute frequency of a light source can be accurately measured by interfering it with the nearest tooth on the comb with respect to the OFC reference. The device thus provides a way of making very accurate spectroscopic measurements of atomic and molecular transitions, and offers a versatile and unique way of comparing atomic clocks.

Nobel connections

The OFC was invented by Theodor Hänsch, who together with Jan Hall was awarded the 2005 Nobel prize in physics for its development. Hänsch, together with two of his students, Ronald Holzwarth and Michael Mei, and Alex Cable, founder and president of Thorlabs, set up Menlo Systems in 2001 to establish the technology as a turn-key device that could be used for a range of applications. The company soon received orders for OFC systems from two laboratories in Austria and Italy, and today all major metrology institutes around the globe own one or more Menlo Systems’ OFCs.

The company has continued to lead the way in terms of innovation, quality and performance, with its products used in ground-breaking research as well as in emerging industrial applications. Its flagship FC1500-ULNplus, the world’s most precise optical frequency comb, is now a key technology in the development of optical clocks – which are expected one day to replace the caesium atomic clock as the current standard for defining the second.

“Menlo has recently made relevant leaps that would have seemed impossible a few years ago for researchers in quantum optics, atomic and molecular physics,” says Michele Giunta, project leader at Menlo and a doctoral candidate in Hänsch’s group at the Max-Planck-Institut für Quantenoptik. “We have developed and conceived frequency combs synthesizing optical frequencies that mimic the sub-hertz linewidth of our ORS ultrastable laser, and it is even ready to support future sub-mHz linewidth lasers. In this way, every frequency generated by the OFC is phase-coherent with the optical reference and exhibits the same linewidth of the reference with a negligible additive noise.”

This technology is exploited in the FC1500-ULNplus, allowing the optical coherence of the reference to be transferred to all lasers locked to the comb, even for the narrowest linewidth laser demonstrated so far. “This product can be used to compare two or more different optical clocks, having the comb keep pace with the best one, and at same time avoid hindering the comparison against the others,” explains Giunta. “It is also used for precision spectroscopy of hydrogen – which is a long-standing research effort led by Theodor Hänsch – to test quantum electrodynamics, and making it possible to determine fundamental constants such as the Rydberg constant or the proton charge radius (Science 358 79).”

The role of the optical reference system, which comprises a continuous wave (CW)-laser locked to a stabilized high-finesse optical cavity, is to allow the comb to reduce the noise of each optical tooth down to the sub-Hertz level. “By doing this we control the two degrees of freedom of the comb with very high bandwidth and unrivalled coherence,” explains Giunta. “In fact, we have recently demonstrated and reported the lowest noise synthesis for both optical and microwave carriers using such a system.”

Record breaker

In 2016, in a collaboration with academic partners at SYRTE, the National Metrology Institute of France – Yann Le Coq and Giorgio Santarelli, who is now at LP2N in Bordeaux – Menlo demonstrated that this technology can be used to synthesize microwaves with the highest spectral purity demonstrated to date.

“Menlo’s technology allows to transfer the frequency stability of the reference laser to the timing of the comb laser pulse train, and hence to a microwave frequency that is detected as the pulse repetition rate,” says Giunta. “The sub-hertz optical linewidth of the reference laser is translated into a microhertz linewidth in the microwave carrier, which is typically a harmonic of the pulse repetition rate.”

This advance in ultralow-noise microwave generation could directly impact on applications such as high-speed data transmission, high-stability atomic clocks, synchronization of Very Long Baseline Interferometry (VLBI), radio astronomy and high-accuracy radar for surveillance and navigation systems.

“In Doppler radar and moving traffic indicator systems, for example, oscillator phase noise causes large stationary clutter to spread through the Doppler spectrum,” explains Giunta. “Consequently, the performance of radar systems is strongly affected by the phase noise characteristics of the microwave oscillator. Low close-in phase noise, at offset frequencies of 1 Hz to 100 kHz, is of critical importance for high-fidelity radar systems.”

Emerging applications

Other high-end applications of frequency comb technology include high-speed precision distance measurements, such as co-ordinating the positioning of satellite swarms, telecommunications, and calibrating astronomic spectrographs, adds Richard Zeltner, head of business development at Menlo.

“We work very closely with research and metrology institutes to find out where different fields are heading and how we can serve them,” he says. “As today’s research can turn into tomorrow’s products, we are striving to develop reliable technology that fulfils the needs of upcoming high-end applications.”

What is a frequency comb?

Zeltner also points out that Menlo continues to make its established products more reliable and user-friendly. “Following more than 15 years of development we recently succeeded in reducing the footprint and ease-of-use of an OFC,” he says. “The SmartComb is a simple and fully autonomous comb system that, together with our ORS ultra-stable laser, provides end-users with a rack-mountable solution for synthesizing sub-Hertz linewidth laser light and extremely pure microwaves.” The SmartComb can easily be used by non-experts, which makes it accessible to a broader clientele.

But the company is aiming even higher, adds Zeltner. Since precise timekeeping and synchronization are both crucial for global navigation satellite systems (GNSS), there are ongoing efforts to qualify optical-clock technology for space applications. “As OFCs are an integral part of any optical clock, Menlo is undertaking R&D efforts in this direction as well,” he says.

A SmartComb was recently operated successfully onboard a high-altitude research aircraft, while a prototype comb was tested under micro-gravity conditions on a sounding rocket that was part of the DLR Texus programme. “We are not quite at a readiness level for in-orbit verification satellite missions or the ISS, but we are making continuous progress towards that goal,” says Zeltner.

Looking to the future

Several other potential applications are also appearing on the horizon, such as comb-assisted coherent control of multiple lasers is one. “This could be important for future ion or neural atom-based quantum computers,” says Giunta. “These emerging technologies could come useful in a multitude of areas and, again, the OFC will be of central importance for such an information technology revolution.”

OFCs are Menlo’s star products, with more than 300 systems currently in operation around the world, but its product portfolio also includes femtosecond lasers, ultrastable CW lasers and THz technology. The company today employs more than 100 people and has offices in Germany, the US and China.

Further reading

Menlo Systems has published a number of scientific papers on photonic microwave generation’s publications, the FC1500-ULNplus, and applications in the space arena:

M Giunta et al. 2019 “Real-time phase tracking for wide-band optical frequency measurements at the 20th decimal place” Nat. Photon. (2019).

E Oelker et al. 2019 “Demonstration of 4.8 × 10−17 stability at 1 s for two independent optical clocks” Nat. Photon. 13 714

X Xie et al. 2016 “Photonic microwave signals with zeptosecond-level absolute timing noise” Nat. Photon. 11 44

J W Zobel et al. 2019 “Comparison of Optical Frequency Comb and Sapphire Loaded Cavity Microwave Oscillators” IEEE Photonics Technol. Lett. 31 1323

M Lezius et al. 2016 “Space-borne frequency comb metrology” Optica 3 1381